Imagine a future in which sewage sludge is not just a disgusting and dirty residual product from society, but it is also an important component for green, sustainable industries. A future in which carbon, phosphorus, nitrogen and other valuable elements can be extracted and recycled in a circular system, so that nothing goes to waste, but instead replaces the fossil raw materials we are digging out of the ground today. This is the aim of Associate Professor Patrick Biller’s research, which takes outset in the hydrothermal liquefaction (HTL) technology: a process that mimics the geological processes that originally led to the production of fossil fuels on Earth.

2023 Grundfos Prize Lecture – Patrick Biller from Grundfos Foundation | PDJF on Vimeo.

Patrick Biller received the Grundfos Prize at a ceremony in Bjerringbro on the 9th of November 2023. The prize consists of the sculpture “Be-Think-Innovate” by artist Flemming Brylle and a cash payment of DKK 1 million, of which DKK 250,000 goes directly to the recipient of the prize, whilst the remaining DKK 750,000 is allocated to further research in the field.

“Receiving the Grundfos Prize is a great honour. I’m greatly motivated when I see that my work has an impact on society and on people. That I’m doing something right. Something good. And that we’re not just a bunch of nerds locked away in our labs working on something deeply nerdy. Because really that’s what we do. But it has huge perspectives,” says the associate professor.

2023 Grundfos Prize laureate: Patrick Biller from Grundfos Foundation | PDJF on Vimeo.

Didn’t want to work in the car industry like everyone else

Patrick Biller was born and raised in Germany, but he decided to study energy and environmental engineering at the University of Leeds after upper secondary school. His interest stemmed from climate and environmental issues, an interest in renewable energy, and good job opportunities at the end.

“Becoming an engineer was simply the logical choice. In Germany, it’s very common to become a mechanical engineer and get a job in the motor industry, but I was much more interested in the environment,” he says.

He had never seriously considered a career in research, but the opportunity presented itself at the end of his Master’s degree, when one of Patrick’s professors asked him if he wanted to do a PhD.

“I had no idea what I was going to do with a PhD, or how a career in research works. But I was happy studying at university, so I thought why not? In fact, a big motivation for me was that I enjoyed research,” says Patrick Biller.

Patrick was recognized for his achievements both during and after his PhD, including the Peter Wilson Medal, awarded annually to a researcher at the University of Leeds who has made an ‘outstanding contribution to postgraduate research’.

He came to Denmark in 2015 and became part of the former Department of Engineering at AU in 2017. In 2019, he received a very prestigious ERC Starting Grant from the EU Research and Innovation Programme Horizon 2020, which accelerated his research and considerably increased the size of his research group.

2023 Grundfos Prize Lecture – Patrick Biller from Grundfos Foundation | PDJF on Vimeo.

When he started the group, it comprised just Patrick himself and one PhD student. The group currently has almost 15 researchers. In 2020, Biller and his research group became part of the Department of Biological and Chemical Engineering at Aarhus University.

Over the years, he has been one of the most important driving forces in the development of HTL worldwide, and he has managed to develop the technology from a few millilitres in laboratories at the University of Leeds back in 2012 to commercial scale in Denmark from 2024.

“Patrick Biller’s research is a premium example of use-inspired and societally relevant research. He has substantially contributed to development and scaling of the liquefaction process, to changing it from a batch to a continuous process, and to the detailed understanding of the liquefaction processes in different feed streams. Patrick Biller has shown remarkable independence while building up the research and education area at the university and collaborated with industry,” says Flemming Konradsen, Chair of the Grundfos Foundation.

Carbon-neutral products from waste

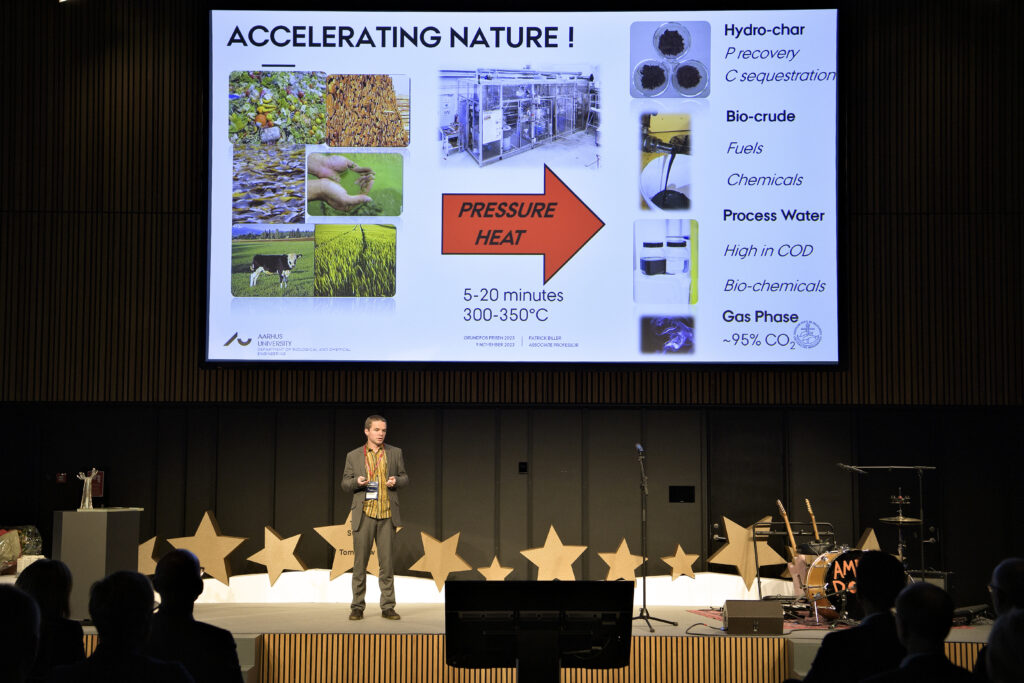

The technology that Patrick Biller has helped develop is based on the same processes that form crude oil in nature. Crude oil is the remnants of microorganisms that, after millions of years of pressure and heat, have been converted from microbial biomass to the raw material we use today in many of our largest industries, from clothing and textiles to fuels, plastics, chemicals and pharmaceuticals.

Like in nature, Patrick uses pressure and heat to convert waste biomass into biocrude that can be upgraded to high-value products such as fuels and platform chemicals. The only difference is that HTL technology dramatically accelerates the process.

“With HTL technology, we can produce carbon-neutral products from renewable resources such as contaminated sludge, which is considered the blackest blackwater waste from society. We can make carbon-neutral products that completely correspond with those we have today. Furthermore we remove pollution from the environment and there’s no compromise on quality,” he says.

Patrick Biller began his research into HTL during his PhD at the University of Leeds, where he worked on growing microalgae and developed a reactor which used HTL technology to convert them into crude oil.

“The process using microalgae was too expensive to be viable because of the high energy costs, and the entire infrastructure was too heavy, but I found that it was possible, and that the technology could be used for a number of other things. I found that a matured technology, applied to an abundant resource, which you might even be paid to remove, could contribute something that could really make sense for society,” he says.

The circular society

Currently, Patrick Biller and his research group, Hydrothermal Processing, are using HTL to convert problematic waste resources such as sewage sludge, food waste or manure – which are often filled with harmful, anthropogenic substances – into high-value products.

The waste is often difficult to manage and highly contaminated: there is usually too much of it, and it is difficult to exploit. However, in a circular society, we need to recycle all our waste and extract vital resources from it.

Take phosphorus for example. It is a valuable and scarce resource, and it is ranked among the top 20 most critical raw materials by the EU. Europe does not have its own phosphorus reserves in the subsoil. Therefore, these are primarily imported from North Africa, where phosphorus is mined as phosphate rock (phosphorite).

Mining as well as refining and transporting phosphorite for fertilizer entails significant emissions of greenhouse gases. Phosphorite is also a limited resource. There are only enough phosphorus resources for another 50-100 years. Running out of phosphorus will have major consequences for humanity, because phosphorus is vital for food production, if we want to maintain the yields modern agriculture can provide.

“We’ve had consumption without recycling for far too long. We continue to pump environmentally problematic substances into nature, and obviously, this ultimately causes problems. Phosphorus and nitrogen are examples of resources that we can extract from sewage sludge using HTL without also extracting the harmful products also found in sludge such as heavy metals, antibiotics, pesticides and microplastics,” says the associate professor.

Sustainable carbon sources

The green transition calls for technologies that can break with the dependence on oil that currently burdens our carbon-based manufacturing industries.

This requires a completely new industrial infrastructure: a rethinking of the way we produce, centred on a far better and more efficient exploitation of waste streams in order to recycle the carbon in society’s food chain, for example.

“There’s a shortage of sustainable carbon sources. We’re doing well in electrifying society and the transport sector and heating systems, but there’s a great need for carbon for a wide range of industries that today are hugely dependent on carbon from oil, like shipping, aviation and the chemical industry,” says Patrick Biller, and he continues:

“HTL is just such a technology that can convert waste as a renewable carbon source into the raw materials our society and industry so desperately need.”

Aarhus University inaugurated one of the world’s largest HTL test facilities for biomass at AU Viborg in 2015, and since then, AU researchers and Patrick Biller have been working to optimise the process by increasing energy efficiency and maximising the recovery of carbon, phosphorous and nitrogen. In early 2024, the researchers and industrial partners will move their experimental activities out of the laboratory to the wastewater treatment plant in Fredericia, where HTL will be implemented commercially in full scale for the first time in Denmark, with direct use of the fuel produced at a refinery located a few kilometres away.

“We’re seeing huge interest in this. Many companies want to use the technology and can see the value in it. They can see that it works. I believe that a large number of HTL facilities will spring up within the next three years,” says the associate professor.

Patrick Biller lives in Aarhus. He is married and has one child.